Berkeley researchers find low-tech solutions for high-tech equipment.

While fielding questions as a guest lecturer at a university in Lima, Peru, Berkeley engineering postdoctoral researcher Lina Nilsson was delighted by the students’ eloquence and insight. “Then we toured the labs,” Nilsson said. “And there was nothing.” She remembers standing amidst a scant collection of basic lab equipment unfit for any advanced research. The students may have been shrewd and intuitive, but they had nowhere to practice, much less to explore.

That was in 2008. Since her return, Nilsson has found a way to help these bright young students with limited access. The solution came to her when she visited Berkeley professor Eva Harris’s Sustainable Sciences Institute. She spotted a centrifuge made from a blender and an agitator made from an old record player—equipment that worked and certainly wasn’t expensive.

Nilsson immediately thought of her visit to Lima. If those students could acquire or build this type of equipment, they could finally conduct proper university research.

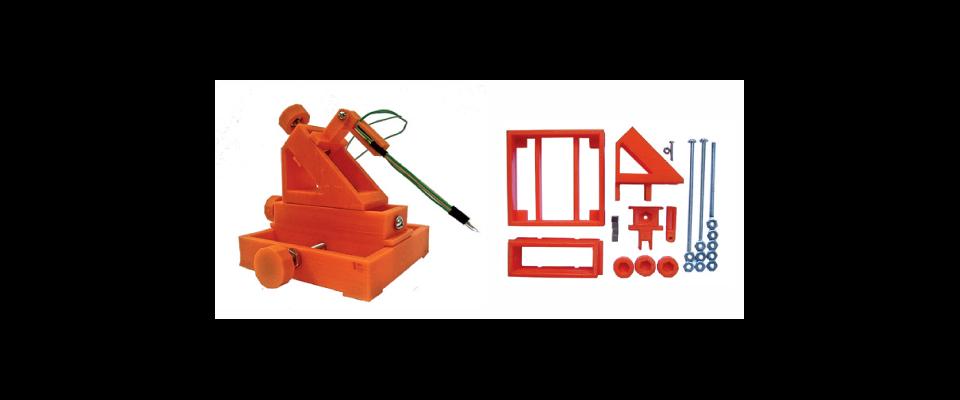

Today, Nilsson and her partner, graduate student Bertram Koelsch, head Tekla Labs, a flourishing Do-It-Yourself [DIY] project that encourages the design and construction of low-cost lab equipment. Their paper, “Bridging the Gap in Higher Education between the Developed and the Developing World,” won the 2010 Berkeley Science, Technology, Engineering, and Policy Group White Paper competition, and their project, Tekla Labs, won the 2010–11 Big Ideas @ Berkeley competition. Motivated by the widespread success of DIY projects such as Instructables and iFixit, Nilsson sought to funnel the enthusiasm for DIY projects into research-grade science experiments.

“Part of the inspiration for doing Tekla as a DIY was simple,” Nilsson said. “What can you realistically do as a postdoc or student? We can’t start a huge non-profit or buy [a] lot of equipment on the side. It matches what we can do with something that has impact.”

Tekla’s mission to create “free and interactive instructions on building standard laboratory equipment using locally available supplies” caught immediate notice from aspiring engineers around the world, who network through the organization’s site to share designs and low-cost solutions. Tekla is run by Nilsson along with seven graduate students, and their project also sponsors a student-run DeCal course called “Engineering World Health.”

Berkeley students started approaching Nilsson and international students began writing to her. Letters came from countries around the world, including New Zealand, Peru, and Colombia. One person built a photometer with LED lights. Undergraduate Anthony Fernando built a sample rotator with a toy motor with two metal parts. Sample rotators, which are standard pieces of lab equipment used to mix samples, usually cost hundreds of dollars. Fernando’s required a motor from the lab and $40 worth of metal.

“We’re just starting out, but our project is already globally distributed,” Nilsson said. “Science is moving in all kinds of different directions. I think it makes our project very powerful.”