As flocks of wild turkeys and geese look on, about 50 members of the UC Berkeley Solar Vehicle Team—aka CalSol—are laboring from dawn to dusk every day at the Richmond Field Station, a 152-acre lot six miles northwest of campus. Their goal: the construction of “Zephyr,” a solar-powered car that can cruise along at 55 miles per hour on only the energy needed for a portable hairdryer.

It’s Cal’s latest entry in an international collegiate competition that has been going on since the early 1990s, before many of CalSol’s current members were born.

In odd years, CalSol competes in the World Solar Challenge, a race halfway across the Australian continent. In even years, the team races halfway across the United States in the American Solar Challenge. And with only six months left until the 2014 challenge, which will run from Texas to Minnesota, its members work with a dedication that eclipses everything else in their lives.

“We’re full-time CalSol members and part-time students,” confesses team leader Min Ju Lee, a materials science and engineering major. “We’re theoretically an undergraduate organization, but people want to stick around after graduation because it’s so awesome, so we don’t kick anybody out.”

The day when solar-powered cars dominate the freeways won’t arrive next week, or even next year. But Nick McKibben, product development engineer at the San Jose–based company SunPower says that when it does, we will all owe a debt to the students at CalSol. “Their work will be integral in future, more practical, solar-powered vehicle design,” he says.

Zephyr is CalSol’s eighth generation of cars. The first three—”California Dreamin’ ” (1993), “Afterburner II” (1997), and “Third Degree Burner” (1999)—were built in collaboration with CalSol’s counterparts at Stanford, under the combined name Team Stanley (the name an amalgam of Stanford and Berkeley).

“They had the facilities, and we had the manpower,” says Pol Llado, an electrical engineering and computer science major who heads the electrical team on Zephyr.

But in 2002 the two teams had an amicable divorce.

“It was just too much of a hassle to travel down there,” Llado explains. They celebrated the split by naming the next car “Solar Bear” (2003), followed by “Beam Machine” (2005), “Goldrush” (2009), and “Impulse” (2011), which finished fourth in the 2012 American Solar Challenge.

“That’s pretty good, considering that we’re running on a very modest budget compared to other solar car teams,” Llado says. “The team from Michigan gets tons of money from the Detroit automakers, so they run on upwards of a million dollars for every car. That’s literally a magnitude of difference, so we have to be cognizant of every purchase we make.

“But there’s also an upside. Other teams have a company making their parts for them, but we don’t have that kind of money. So we make as many parts as we can ourselves, and that gives us a much deeper understanding of how things work.”

CalSol gets some financial help from companies such as Volkswagen, which gives periodic $25,000 grants, and Linear Technology in Milpitas, which prints their electrical circuits and donates $8,000 per year.

“And every semester, several of their engineers drive up to Cal to demonstrate the cool stuff they’re making and give us freebies to play with,” says Lee.

SunPower, which makes their solar cells, also provides valuable mentoring in the person of McKibben. “These students are doing important work, including ways to maximize solar cell area while minimizing aerodynamic drag,” he says. “They’re learning how to challenge industry norms and rapidly innovate, which is really inspiring.”

Each successive CalSol vehicle has been a quantum leap over its predecessor, and Zephyr is no different.

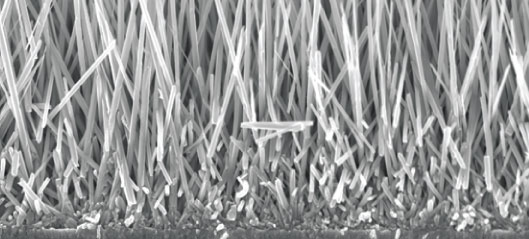

“We’re targeting the heaviest elephants first,” says Brian Graf, a mechanical engineering major who supervised the car’s mechanical design. “Our previous solar cars used a wet layup composite for the aerodynamic shell. You take dry fabric, add epoxy resin, make the whole thing wet, shape it into a mold, and when it dries you pop it out of the mold and you have your car.

“The problem is that this process is subject to humans—us—pouring in too much resin, making it heaver than it needs to be. So for Zephyr, we are using pre-impregnated composites, which have the perfect ratio of resin to carbon fiber fabric. Making this switch will reduce the weight of the car by approximately 100 pounds, just from that change alone.

“The second big change,” Graf continues, “is that the structural chassis will be made of aluminum instead of steel. This should further reduce the weight of the chassis by 30 percent, and every pound counts.

“Finally, we’re reducing the weight of the suspension system another 30 pounds by utilizing a 7000-series aluminum, which is aircraft grade, rather than the 6000-series common grade. That will provide more strength to weight for all of the individual suspension components.”

The drive train is getting an upgrade, too—it’s expected to operate at more than 98 percent efficiency (regular cars are lucky to get a drive train efficiency of 30 percent.)

“Our strength was our reliability. We had no breakdowns during the race. While other teams had problems driving in the rain, we just kept chugging along.”

The 2014 American Solar Challenge starts in Austin on July 21 and finishes in Minnesota’s Twin Cities on July 28, with scheduled stops along the way. Each competing car will be preceded by a lead vehicle and followed by a chase vehicle monitoring the car’s condition and a van carrying spare parts. All will stay in constant radio contact.

“We had a problem with that during a rainstorm in the 2012 American Solar Challenge,” says Mike Vogel, an electrical engineering and computer science major who was a team leader that year. “We mounted one of our radios right behind the driver, in front of the rear wheel, and when the wheel spun on the wet surface, it sprayed water on the radio, and that fried the radio. The telemetry system—the black box—couldn’t tell the chase vehicle what condition the car was in. All we had was feedback from the driver giving his best guess as to what was going on. It was fun, but it was also terrifying.”

So how did Impulse managed to finish fourth? “Our strength was our reliability,” says Llado. “We had no breakdowns during the race. While other teams had problems driving in the rain, we just kept chugging along.”

The CalSol team also benefited from the generosity of their competitors, especially the team from Oregon State.

“The general understanding is that everyone helps everyone else,” says Vogel. “Everyone wants everybody else to succeed. Oregon State had a relatively good working car and a large quantity of spare parts, so they ended up wandering around to other teams, helping out where they could, lending spare parts, and troubleshooting problems.

“The only team that was cutthroat and competitive was Michigan. With their budget, they were in a league of their own. They finished ten hours ahead of the second car. We didn’t see much of them.”

Although many of the technical challenges have been solved, a few problems remain to be ironed out before July, so CalSol members are putting in long hours at the Richmond Field Station. When it’s too dark to keep working, they end the day with a killer barbecue.

“We started out with simple frozen hamburgers,” says Graf, who serves as CalSol’s official burger meister. “We had to start slow and easy to build up our grilling chops.”

Next, they started grilling chili-lime shish kebabs, which were a big improvement, and now they’ve moved to round three: back to burgers, but made from scratch this time with minced onions, teriyaki sauce, and other seasonings.

They follow one rule of etiquette, according to Lee: Never, ever eat anything that falls on the ground.

“They used to make ammunition here during World War II, and we’ve been told not to eat the dirt,” she says. “It has some really nasty stuff in it. Around here, the five-second rule doesn’t apply.”

So what’s the future of solar-powered vehicles?

“Theoretically, physics tells us we cannot physically harvest more than 57 percent of the sun’s energy by solar panels,” says Vogel. “That works out to somewhere from 3.5 to 4 kilowatts per meter. If you imagine the area of the car, that’s not a lot of energy.”

As a result, he predicts the car of the future will not be directly solar-powered. It will be something similar to a Tesla, with a large battery storage unit that can be refilled by plugging the car into expansive solar arrays. In other words, says Vogel, “it won’t be enough to drive into your loal Arco and say ‘Can I use your outlet?’ ”

To support CalSol, donate online at calsol.berkeley.edu or mail checks, payable to “ASUC/CalSol,” to CalSol, 6141 Etcheverry Hall, Berkeley, CA 94720.